Valve e Felletseng ea ho Chesa Ball

Valve ea Bolo e Felletseng ea Weld ke Eng?

Valve ea bolo ke e 'ngoe ea li-valve tse tsebahalang haholo bakeng sa liindasteri tse fapaneng. Ka tse joaloLikaroloanae le khanyetso e nyane ea mokelikeli, kanale e phallang hantle, ho buloa le ho koaloa ka potlako, le taolo e bonolo ea othomathiki, valve ea bolo e sebelisitsoe haholo. Empa li-valve tsa setulo kapa tsa bolo tse tloaelehileng hangata li entsoe ka PTFE le lisebelisoa tse ling tse seng tsa tšepe. Li lekanyelitsoe ke thepa ea tiiso ea setulo, li-valve tse tloaelehileng li ke ke tsa sebelisoa tlas'a boemo ba ts'ebeletso ba mocheso o phahameng kapa khanyetso ea ho tsofala.

Ka hona, letoto la mekhoa e mecha ea setaelel li-valve tsa bolo tse lutseng ka tšepee ne e lee ntlafalitsoe, 'meli sebelisitsoe haholo peteroleng, indastering ea lik'hemik'hale, matla a motlakase, tšepe, indasteri ea leseli jj.

Valve ea bolo ea setulo sa tšepe ho ea ho tšepe ha e na melemo e fapaneng ea li-valve tsa bolo tsa indasteri tse tloaelehileng feela, empa hape e na le litšobotsi tse ikhethang le tse ikhethang tsa ho tšoarella mochesong, haholo-holo ha tiiso e bonolo e sa khone ho sebelisoa, joalo ka ho tsamaisoa ha liphaephe tsa metsi a mahareng a nang le lerōle le phahameng la khohlano, slurry, le motsoako o tiileng oa lintho tse tsoang kantle ho naha.

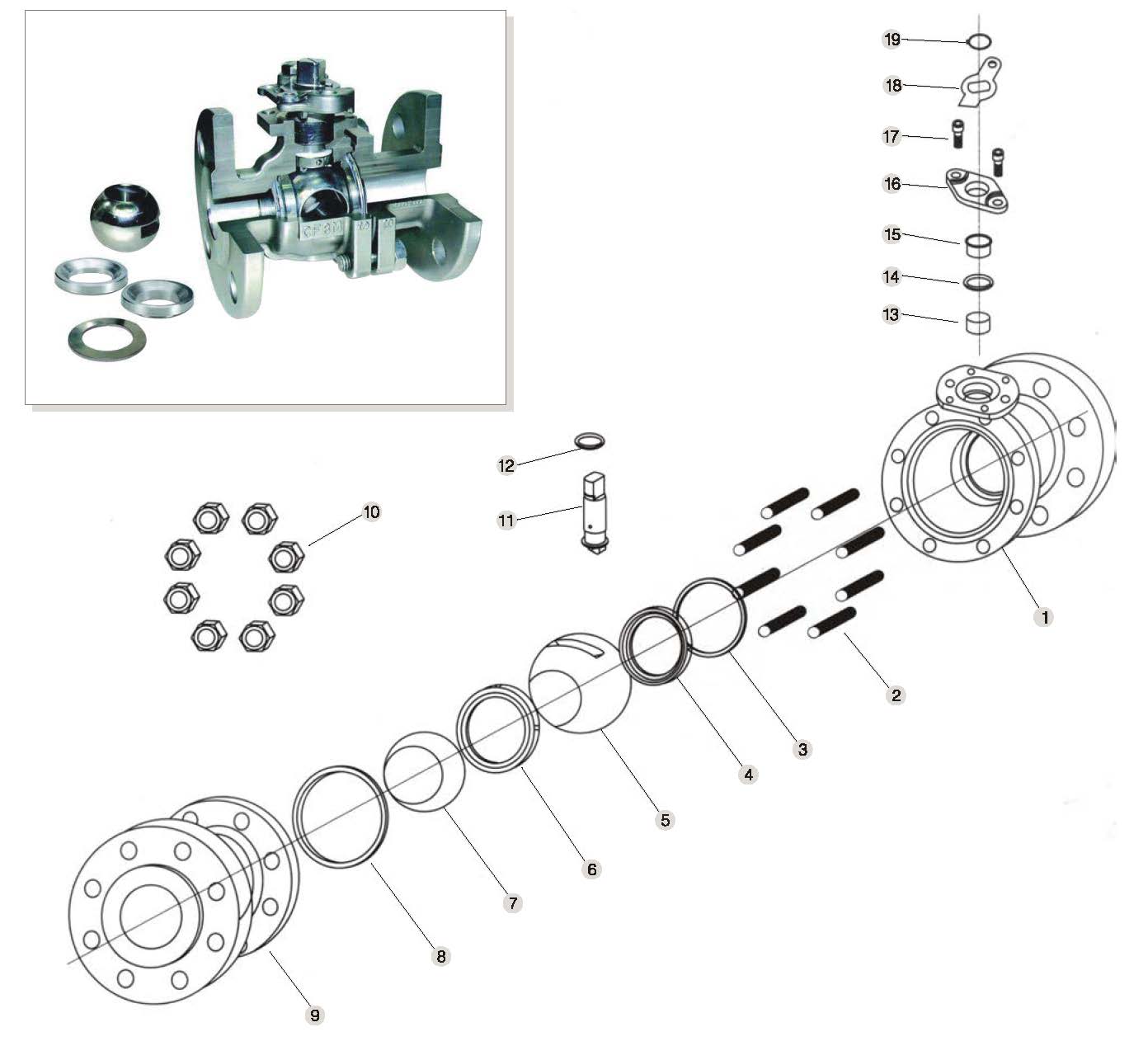

Likarolo tsa mantlha tsa Valve ea Bolo e Felletseng ea Weld?

1.Theknoloji ea ho thatafatsa bolo le setulo e tsoetseng pele

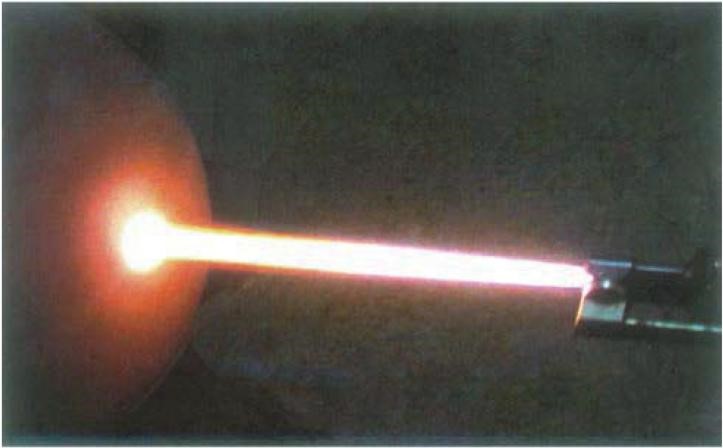

Ho kwalwa ho etswa ka tshepe ho ya dijong pakeng tsa bolo le setulo sa tshepe sa di-valve tsa bolo. Ho ya ka maemo a fapaneng a tshebeletso le ditlhoko tsa basebedisi, mahlale a fapaneng a tsoetseng pele a ho thatafatsa bolo le setulo a ka sebediswa, ho kenyeletswa le ho kwalwa ha HVOF, ho welding ya spray ya nickel-base alloy, ho welding ya spray ya nickel alloy e phahameng, ho welding ya spray ya cobalt case hard alloy, jj. Ka kakaretso bothata ba bokahodimo ba bolo le setulo bo ka fihla ho HRC55-60 ka boleng bo hodimo ba HRC70. mme ka tlwaelo, ho hanyetsa mocheso ha thepa ya sefahleho sa ho kwalwa e ka ba 540°C, ka boleng bo hodimo ba 980°C. Thepa ya sefahleho sa ho kwalwa e boetse e na le tshebetso e ntle e hanelang ho tlola le e hanelang ho tshusumetso.

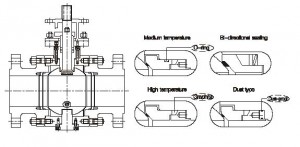

2. Ho Buloa le ho Koaloa ha Valve e Tenyetsehang

Tlas'a boemo ba tšebeletso ba mocheso o phahameng, bolo le setulo li tla atoloha haholo ka lebaka la katoloso ea mocheso, 'me torque e tla eketseha' me valve e ke ke ea buloa, Valve ea bolo e amohela sebopeho sa ho koala sa diski kapa sa selemo se tletseng e le hore katoloso ea mocheso ea likarolo tse tlas'a mocheso o phahameng e ka monngoa ke diski kapa selemo. 'Me ho netefatsoa hore valve e tla buloa le ho koaloa ka mokhoa o tenyetsehang tlas'a mocheso o phahameng ntle le ho atoloha haholo.

3. Moralo oa Sebopeho se sa Cheseng

Sebopehong sa tšepe ho tloha ho tšepe ho ea ho tšepe bakeng sa valve, gasket ke tšepe e sa hloekang + graphite e tenyetsehang 'me sephutheloana ke graphite e tenyetsehang. Ka hona, ho tiisoa ka mokhoa o tšepahalang ha valve ho ka netefatsoa esita le haeba ho ka cha.

4. Double Block le ho tsoa mali (Tšepe e lutseng Trunnion Ball Valve)

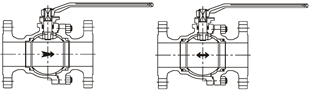

Hangata valafo ea tšepe e lutseng holim'a trunnion e sebelisa sebopeho sa ho koala pele ho bolo. Ha valafo e koetsoe 'me sebaka se bohareng se ntšoa valafo ea ho ntša metsi, litulo tse holimo le tse tlase li tla thibela mokelikeli ka boikemelo ho kena le ho tsoa ho fihlela tšebetso ea li-block tse peli.

Valve ea bolo e phaphametseng e lutseng ka tšepe hangata e amohela sebopeho sa ho koala kamora bolo. Tsela ea phallo e tla tšoauoa 'meleng bakeng sa ho koala valve ea bolo ka tsela e le' ngoe. Haeba ho boletsoe ke basebelisi ba ho qetela, ho koala ka tsela e 'ngoe ho ka etsoa.

5. Tshebetso e Tšepahalang ea ho Tiisa

Theknoloji e ikhethang ea ho sila bolo e amoheloa, ka ho potoloha ha bolo le grinder maemong a fapaneng. Bokaholimo ba bolo bo tla fihlela ho chitja le ho ba botenya bo phahameng. Ho koaloa ha setulo sa valve ka khatello e tlase ho bonoa ka ho tiisoa esale pele ha selemo. Ho phaella moo, phello ea piston ea setulo sa valve e entsoe ka mokhoa o utloahalang, e leng se etsang hore ho tiisoa ha khatello e phahameng ke maro ka boeona, ho tiea ha li-valve tsa bolo tse lutseng ka tšepe ho fihlela litlhoko tsa boemo ba IV ba ANSI B16.104.

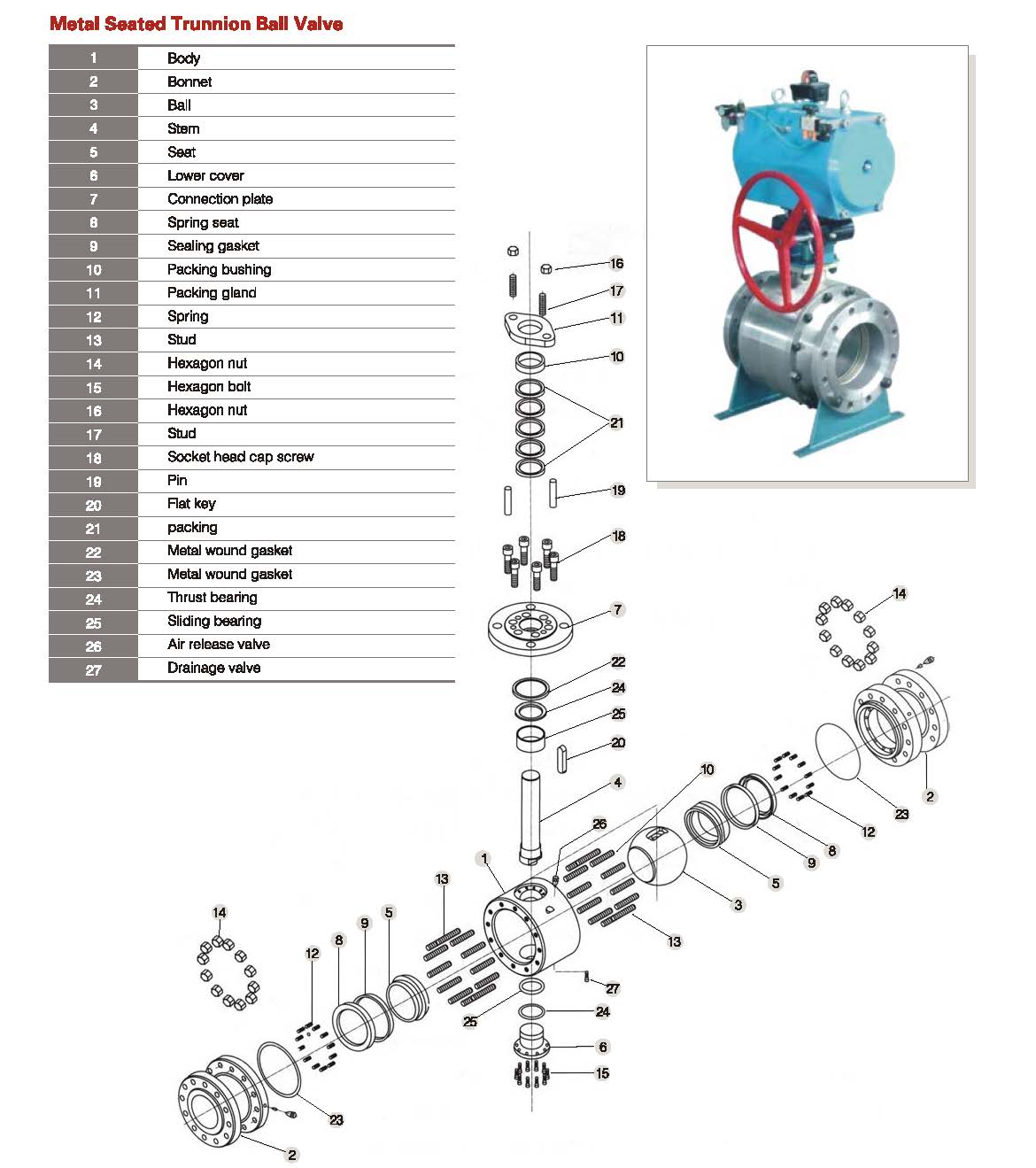

Valve ea bolo ea trunnion e lutseng ka tšepe

Tšepe e lutseng phaphametseng ea bolo ea tšepe

Litlhaloso tsa tekheniki tsa Valve ea Bolo e Felletseng ea Weld

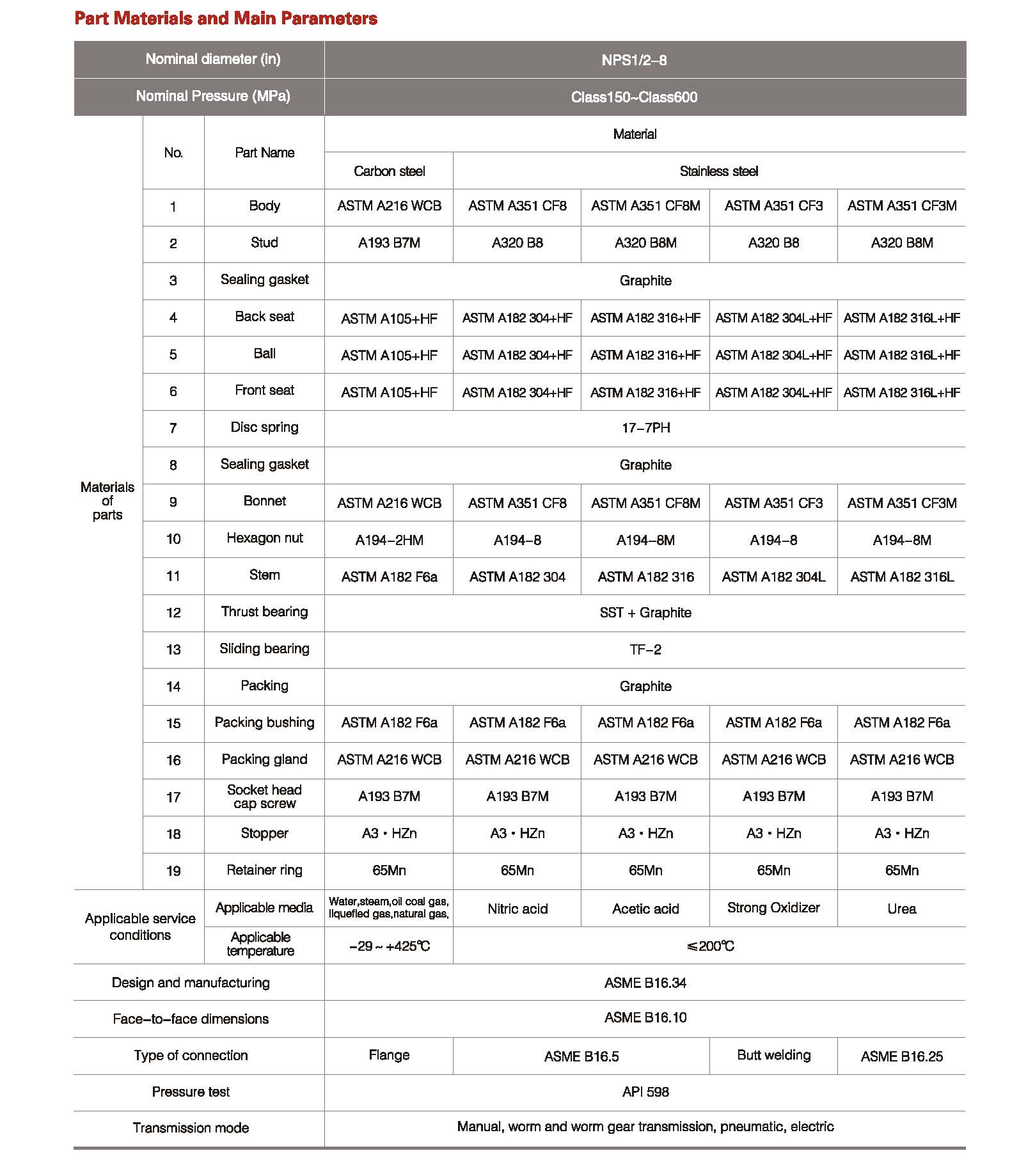

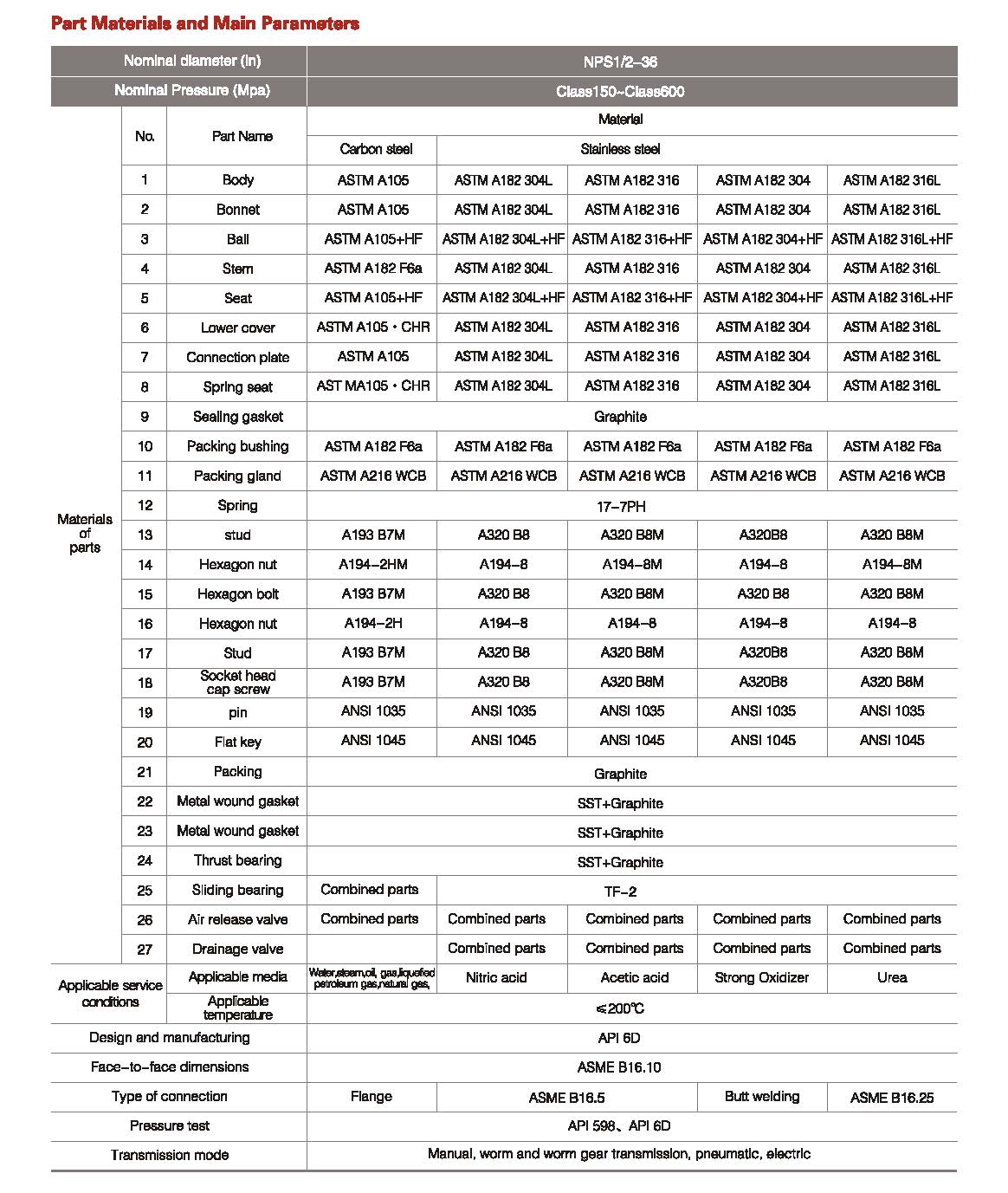

Li-valve tsa bolo tse lutseng ka tšepe, moralo o fapaneng bakeng sa bolo e phaphametseng le bolo ea trunnion.

Li-valve tsa bolo tse phaphametseng tsa tšepe tse lutseng ka tšepe

Valve ea bolo ea trunnion e lutseng ka tšepe

Pontšo ea Sehlahisoa:

Tšebeliso ea Valve ea Bolo e Felletseng ea Weld

Valve ea Tšepe e Lulang ka Bolo e sebelisetsoa eng?

Thevalafo ea bolo e lutseng ka tšepee sebelisoa haholo ho khaola kapa ho hokahanya mecha ea phatlalatso liphaepheng tse fapaneng, peterole, indasteri ea lik'hemik'hale, motlakase, tšepe, indasteri ea mabone. E loketse maemo a boima a ts'ebeletso a nang le li-granule tse tiileng, slurry, phofo ea mashala, cinder jj.